What Makes Pneumatic Actuators Indispensable in Industrial Automation?

2025-10-15

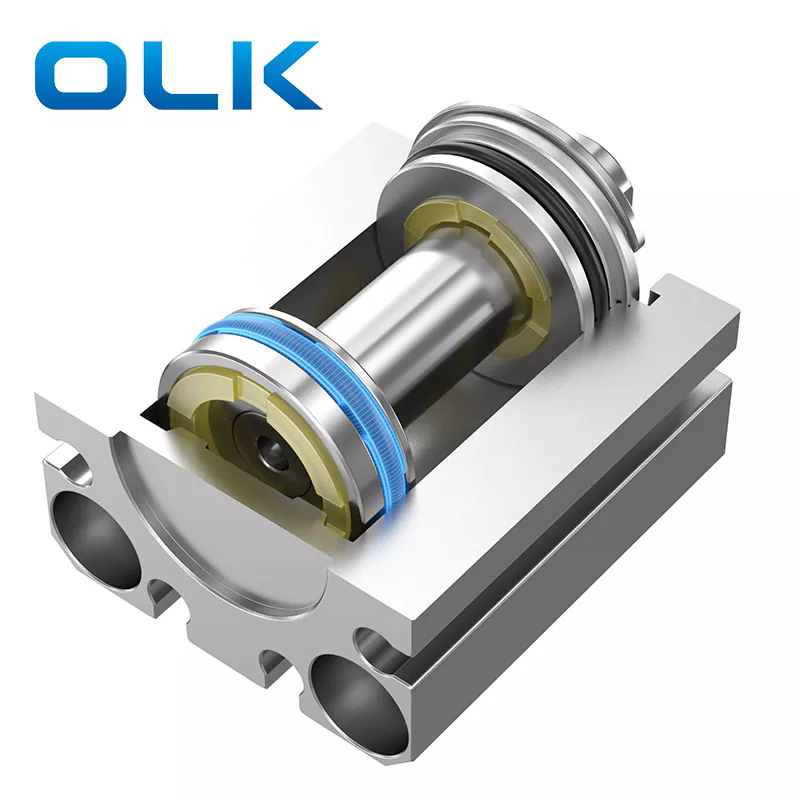

Pneumatic actuators are pivotal components in industrial automation, offering reliable, fast, and precise motion control solutions. These devices convert compressed air energy into mechanical motion, enabling a wide range of industrial applications, from valve automation to assembly line operations. The growing demand for efficient, safe, and cost-effective actuation systems has made pneumatic actuators an integral part of modern manufacturing, energy, and processing industries.

What Are Pneumatic Actuators and How Do They Work?

Pneumatic actuators are mechanical devices designed to generate linear or rotary motion using compressed air. Their operational principle is based on converting air pressure into mechanical energy, which then moves a piston or a diaphragm to perform work. Depending on the configuration, pneumatic actuators can deliver precise linear or rotary displacement, making them suitable for a variety of applications, such as controlling valves, lifting loads, or driving robotic arms.

Types of Pneumatic Actuators:

-

Linear Actuators: Produce straight-line motion and are commonly used for valve operation and material handling.

-

Rotary Actuators: Convert air pressure into rotational motion, suitable for quarter-turn valves and rotary mechanisms.

-

Single-Acting Actuators: Use compressed air for motion in one direction, with spring return for the opposite motion.

-

Double-Acting Actuators: Use air pressure for motion in both directions, providing higher control and repeatability.

How Pneumatic Actuators Operate:

-

Compressed air is introduced into the actuator chamber.

-

The air pressure moves the piston or diaphragm.

-

The mechanical output is transmitted to the connected machinery (e.g., valve stem, lever, or rod).

-

For double-acting actuators, reversing the air flow direction reverses the motion.

Key Benefits:

-

Rapid response and high-speed operation

-

Durable in harsh environments

-

Simplified maintenance

-

Low operational cost due to absence of electrical components

-

Intrinsically safe in explosive atmospheres

Why Are Pneumatic Actuators a Preferred Choice in Industry?

Pneumatic actuators have become a standard in industrial automation for several reasons:

-

Reliability in Extreme Conditions: Pneumatic actuators function efficiently under high temperatures, humidity, and dusty environments where electric actuators may fail.

-

Cost-Effectiveness: Installation and operational costs are generally lower than equivalent electric or hydraulic systems.

-

Safety: No sparks or electrical components make them ideal for flammable or explosive environments.

-

Precision and Repeatability: Modern designs incorporate positioners and feedback devices to achieve precise control, making them suitable for complex automation tasks.

Applications Across Industries:

| Application | Industry | Function |

|---|---|---|

| Valve Operation | Oil & Gas, Chemical | Control fluid flow with precise positioning |

| Robotics & Automation | Manufacturing, Packaging | Provide rapid, repeatable motion |

| Material Handling | Logistics, Automotive | Lift, push, or rotate objects efficiently |

| HVAC Systems | Commercial Buildings | Automate dampers and ventilation controls |

| Food & Beverage | Processing Plants | Maintain hygiene with non-electric, easy-to-clean actuation |

Why Invest in Advanced Pneumatic Actuators?

-

Enhance operational efficiency and reduce downtime

-

Minimize maintenance efforts with fewer moving parts

-

Adaptable to both small-scale and large-scale industrial applications

How to Choose the Right Pneumatic Actuator?

Selecting the appropriate pneumatic actuator requires careful consideration of several parameters to ensure compatibility and optimal performance:

Critical Selection Factors:

| Parameter | Description | Recommendation |

|---|---|---|

| Bore Size | Diameter of piston chamber, affecting force output | Select according to load requirements |

| Stroke Length | Linear distance traveled by piston | Must match the travel requirement of the application |

| Operating Pressure | Maximum air pressure supported | Ensure it matches facility air supply |

| Torque (for rotary actuators) | Rotational force output | Choose based on valve or device torque demand |

| Material | Aluminum, stainless steel, or carbon steel | Correlate with environmental conditions and corrosion resistance |

| Mounting Options | Direct, bracket, or flange | Should suit existing system installation points |

| Endurance | Number of cycles before maintenance | Select for high-cycle applications in continuous operations |

| Accessories | Positioners, solenoid valves, limit switches | Add for precision control and automation integration |

Common Selection Scenarios:

-

High-Speed Automation: Opt for lightweight, low-inertia actuators for rapid response.

-

Corrosive Environments: Stainless steel actuators ensure longevity.

-

Heavy Load Operations: Larger bore sizes and double-acting configurations provide sufficient force and durability.

Maintenance Considerations:

Regular inspection of seals, lubrication, and air supply quality ensures consistent performance and prolongs the life of the actuator. Integrating actuator monitoring systems can further reduce unplanned downtime.

Future Trends and Common Questions About Pneumatic Actuators

As industrial automation advances, pneumatic actuators continue to evolve, integrating smarter control systems, energy-efficient designs, and adaptive technologies.

Emerging Trends:

-

Smart Pneumatic Actuators: Incorporating IoT sensors for real-time monitoring, predictive maintenance, and process optimization.

-

Energy Efficiency: Improved sealing technologies and low-friction materials reduce compressed air consumption.

-

Hybrid Actuation Systems: Combining pneumatic and electric actuators for applications requiring both speed and precise control.

-

Sustainable Manufacturing: Environmentally friendly actuator materials and reduced energy consumption contribute to greener industrial operations.

Frequently Asked Questions (FAQs):

Q1: How long does a pneumatic actuator typically last?

A1: The lifespan depends on operating conditions, air quality, and cycle frequency. Standard actuators can operate reliably for several million cycles with proper maintenance, while high-end designs with corrosion-resistant materials and enhanced sealing can last longer in harsh industrial environments.

Q2: Can pneumatic actuators be used in hazardous areas?

A2: Yes, they are particularly suited for hazardous environments because they do not generate sparks or heat, making them safe for explosive atmospheres such as chemical plants, oil refineries, and gas processing facilities. Proper selection of materials and compliance with safety certifications (e.g., ATEX, IECEx) is essential.

Pneumatic actuators are central to advancing industrial automation by providing efficient, safe, and high-performance motion control solutions. The continuous evolution of these devices, from smart integration to sustainable design, ensures that industries can meet the growing demand for precision, speed, and reliability.

For those seeking robust and innovative pneumatic actuator solutions, OLK offers a wide range of products designed to meet diverse industrial needs. With high-quality materials, precise engineering, and industry-leading performance, OLK pneumatic actuators are built to last and optimize operational efficiency. For detailed specifications, personalized solutions, or inquiries, contact us today to enhance your automation systems.