What Makes an ISO Pulp And Paper Process Pump Essential for Modern Mills?

2025-12-25

In today's highly competitive pulp and paper industry, efficiency, reliability, and compliance with international standards are no longer optional—they are decisive factors for survival and growth. From raw pulp handling to chemical circulation and wastewater transfer, pumping systems play a critical role in maintaining stable production. An ISO Pulp And Paper Process Pump is specifically engineered to meet these demanding conditions, ensuring smooth operation, reduced downtime, and long-term cost control. By combining standardized dimensions, robust materials, and optimized hydraulic design, ISO-compliant pumps have become a trusted choice for mills seeking consistent performance and global compatibility.

Understanding the ISO Pulp And Paper Process Pump

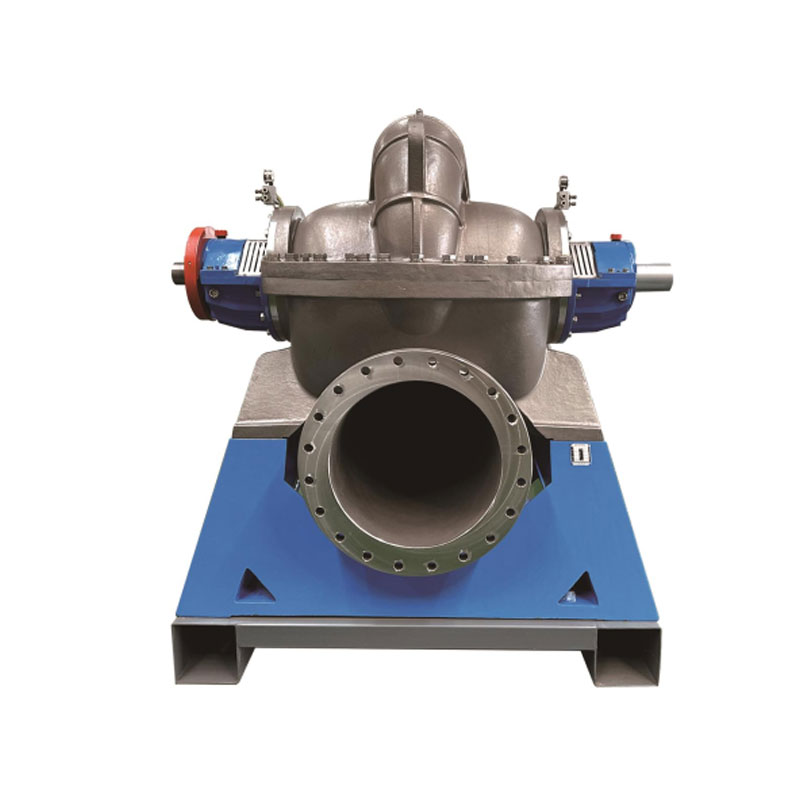

An ISO Pulp And Paper Process Pump is a centrifugal pump designed in accordance with ISO standards (such as ISO 2858 and ISO 5199), widely used in pulp preparation, paper stock transfer, chemical dosing, and recovery systems. These pumps are built to handle abrasive fibers, corrosive chemicals, and high-temperature fluids commonly found in pulp and paper processes.

For manufacturers like Shandong Furkey Pumps Co., Ltd., ISO standards are not just technical benchmarks—they are a commitment to quality, interchangeability, and international acceptance.

Key Functions in Pulp and Paper Production

1. Stable Medium Transfer

ISO pulp and paper pumps ensure continuous and stable transfer of pulp slurry, black liquor, white water, and chemical solutions without clogging or excessive wear.

2. Pressure and Flow Control

They maintain consistent pressure and flow rates, which is essential for uniform paper quality and efficient machine operation.

3. Process Integration

Thanks to standardized dimensions, ISO pumps can be easily integrated into existing production lines or replaced without major system modifications.

Main Applications Across the Industry

-

Pulp stock preparation and screening

-

Chemical circulation (alkali, bleaching agents, additives)

-

White water and wastewater handling

-

Recovery boiler feed and auxiliary systems

These applications demand pumps that can withstand abrasion, corrosion, and continuous operation—exactly where ISO-standard designs excel.

ISO Pulp And Paper Process Pump vs. Non-Standard Pumps

| Comparison Item | ISO Pulp And Paper Process Pump | Non-Standard Industrial Pump |

|---|---|---|

| Design Standard | ISO 2858 / ISO 5199 compliant | Manufacturer-specific |

| Interchangeability | High, global compatibility | Limited |

| Maintenance Cost | Lower due to standard parts | Higher |

| Reliability | Proven and consistent | Varies |

| Export Acceptance | Widely accepted worldwide | Often restricted |

This comparison clearly shows why ISO pumps are preferred by international pulp and paper mills.

Why ISO Standards Matter in Pulp and Paper Operations

Reliability and Safety

ISO standards define strict requirements for shaft strength, casing pressure, and hydraulic performance, ensuring safe long-term operation.

Reduced Downtime

Standardized spare parts and predictable performance minimize maintenance time and unplanned shutdowns.

Global Compatibility

ISO pumps can be replaced or upgraded easily, even across different brands, making them ideal for multinational projects.

Performance Benefits You Can Expect

Using an ISO Pulp And Paper Process Pump from Shandong Furkey Pumps Co., Ltd. delivers measurable results:

-

Improved production stability

-

Reduced energy consumption through optimized hydraulics

-

Longer service life under abrasive and corrosive conditions

-

Lower total cost of ownership (TCO)

These benefits directly translate into higher profitability and operational confidence.

Typical Technical Features

-

Robust cast iron or stainless-steel casing

-

Wear-resistant impeller design for fiber media

-

High-efficiency hydraulic model

-

Standardized shaft seal options (packing or mechanical seal)

Example Specification Overview

| Parameter | Typical Range |

|---|---|

| Flow Capacity | Up to several thousand m³/h |

| Head | Up to 160 m |

| Temperature | Up to 180°C |

| Medium | Pulp slurry, chemicals, water |

The Importance of Choosing the Right Manufacturer

Not all ISO pumps deliver the same performance in real-world pulp and paper environments. Shandong Furkey Pumps Co., Ltd. combines ISO-compliant design with industry-specific optimization, ensuring each pump matches actual operating conditions rather than theoretical parameters.

With extensive experience in industrial pumping solutions, Furkey focuses on:

-

Customized material selection

-

Strict quality control

-

Professional technical support

-

Competitive pricing with global standards

Conclusion: A Smart Investment for Long-Term Efficiency

An ISO Pulp And Paper Process Pump is more than a standardized piece of equipment—it is a strategic investment in production stability, energy efficiency, and international compliance. Whether you are upgrading an existing mill or planning a new project, choosing the right ISO pump partner can significantly impact your operational success.

If you are looking for reliable, high-performance pumping solutions tailored to pulp and paper applications, Shandong Furkey Pumps Co., Ltd. is ready to support your needs. Contact us today to discuss your project requirements and discover how our ISO pulp and paper process pumps can enhance your production efficiency.