Single Stage Lime Grinding Dewatering Pulp Pumps

Single Stage Lime Grinding Dewatering Pulp Pumps Naipu NP-AH(R) series centrifugal slurry pumps and spare parts can fully interchangeable with world famous brand. These pumps are of heavy duty construction, designed for continous pumping of highly abrasive and corrosive slurries. They feature a wide......

Send Inquiry

Product Description

Single Stage Lime Grinding Dewatering Pulp Pumps

Naipu NP-AH(R) series centrifugal slurry pumps and spare parts can fully interchangeable with world famous brand. These pumps are of heavy duty construction, designed for continous pumping of highly abrasive and corrosive slurries. They feature a wide choice of replaceable abrasion resistant metal or molded elastomer casting liners and impellers, which are all interchangeable within a common casting assembly.

Typical Application-

Mineral Flotation Processing

Electric Factory Coal preparation

Coal Washing

Chemical medium processing

Sand and gravel handling

Effluent Handling

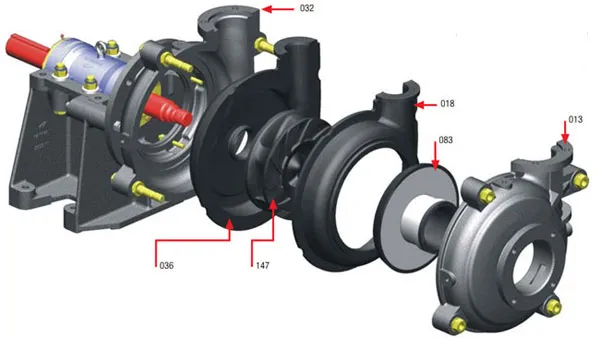

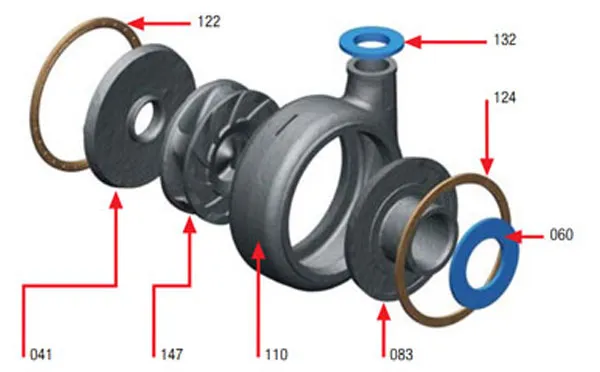

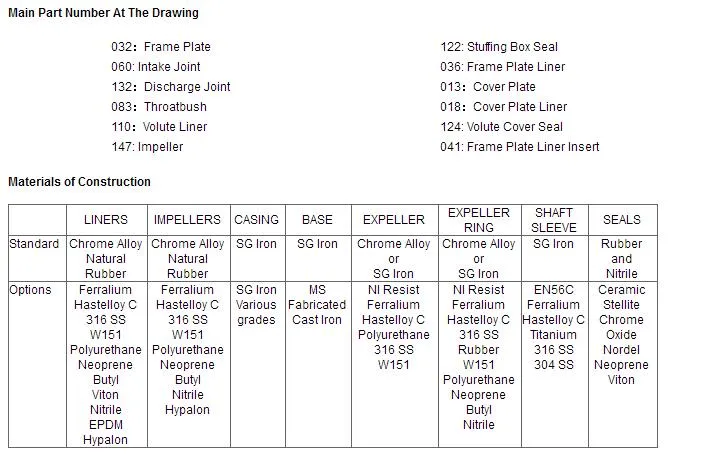

Construction Drawing

Pump Performance Parameters

| Type | Allowable Mating Max. Power(Kw) | Clear Water Performance | Impeller | |||||

| Capacity/Q m³/hr | Head/m | Speed/rpm | Max Efficiency/% | NPSH/m | Nos of Vane | Impeller Diameter/mm | ||

| 1.5X1-NP-NAH | 15 | 12.6--28.8 | 6--68 | 1200--3800 | 40 | 2--4 | 5 | 152 |

| 2X1.5-NP-NAH | 15 | 32.4--72 | 6--58 | 1200--3200 | 45 | 3.5--8 | 5 | 184 |

| 3X2-NP-NAH | 30 | 39.6--86.4 | 12--64 | 1300--2700 | 55 | 4--6 | 5 | 214 |

| 4X3-NP-NAH | 30 | 86.4--198 | 9--52 | 1000--2200 | 71 | 4--6 | 5 | 245 |

| 6X4-NP-NAH | 60 | 162--360 | 12--56 | 800--1550 | 65 | 5--8 | 5 | 365 |

| 8X6-NP-NAH | 300 | 360--828 | 10--61 | 500--1140 | 72 | 2--9 | 5 | 510 |

| 10X8-NP-NAH | 560 | 612--1368 | 11--61 | 400--850 | 71 | 4--10 | 5 | 686 |

| 12X10-NP-NAH | 560 | 936--1980 | 7--68 | 300--800 | 82 | 6 | 5 | 762 |

| 14X12-NP-NAH | 560 | 1260--2772 | 13--63 | 300--600 | 77 | 3--10 | 5 | 965 |

| 16X14-NP-NAH | 1200 | 1368--3060 | 11--63 | 250--550 | 79 | 4--10 | 5 | 1067 |

| 20X18-NP-NAH | 1200 | 2520--5400 | 13--57 | 200--400 | 85 | 5--10 | 5 | 1370 |

Product Overview:

NaiPu Main Pump

The Main pump model of AH HH M L SP AF G Series

| AH series | L(R), M | HH | SP(R) | G | AF Series |

| 1.5/1B-AH(R) | 20A-L | 1.5/1 C-HH | 40PV-SP(R) | 6/4D-G | 2QV-AF |

| 2/1.5B-AH(R) | 50B-L(R) | 3/2D-HH | 65QV-SP(R) | 8/6E-G | 3QV-AF |

| 3/2C-AH(R) | 75C-L | 4/3E-HH | 100RV-SP(R) | 10/8F-G | 6SV-AF |

| 4/3C-AH(R) | 100 D-L | 4/3X-HH | 150SV-SP(R) | 10/8S-G | 8SV-AF |

| 6/4D-AH(R) | 150E-L | 6/4F-HH | 200SV-SP | 12/10G-G | |

| 6/4E-AH(R) | 300S-L | 6/4X-HH | 250TV-SP | 14/12G-G | |

| 8/6E-AH(R) | 10/8 R-M | 6S-H | 14/12T-G | ||

| 8/6R-AH(R) | 10/8 E-M | 8/6S-H | 16/14 G-G | ||

| 10/8F-AH(R) | 8/6X-H | 16/14TU-GH | |||

| 10/8X-AH(R) | 6S-HP | 16/14H-GH | |||

| 12/10ST-AH(R) | 8/6S-HP | 18/16G-G | |||

| 14/12ST-AH(R) | 8/6X-HP | 18/16 TU-GH | |||

| 16/14TU-AH(R) | |||||

| 20/18G(TU)-AH(R) |

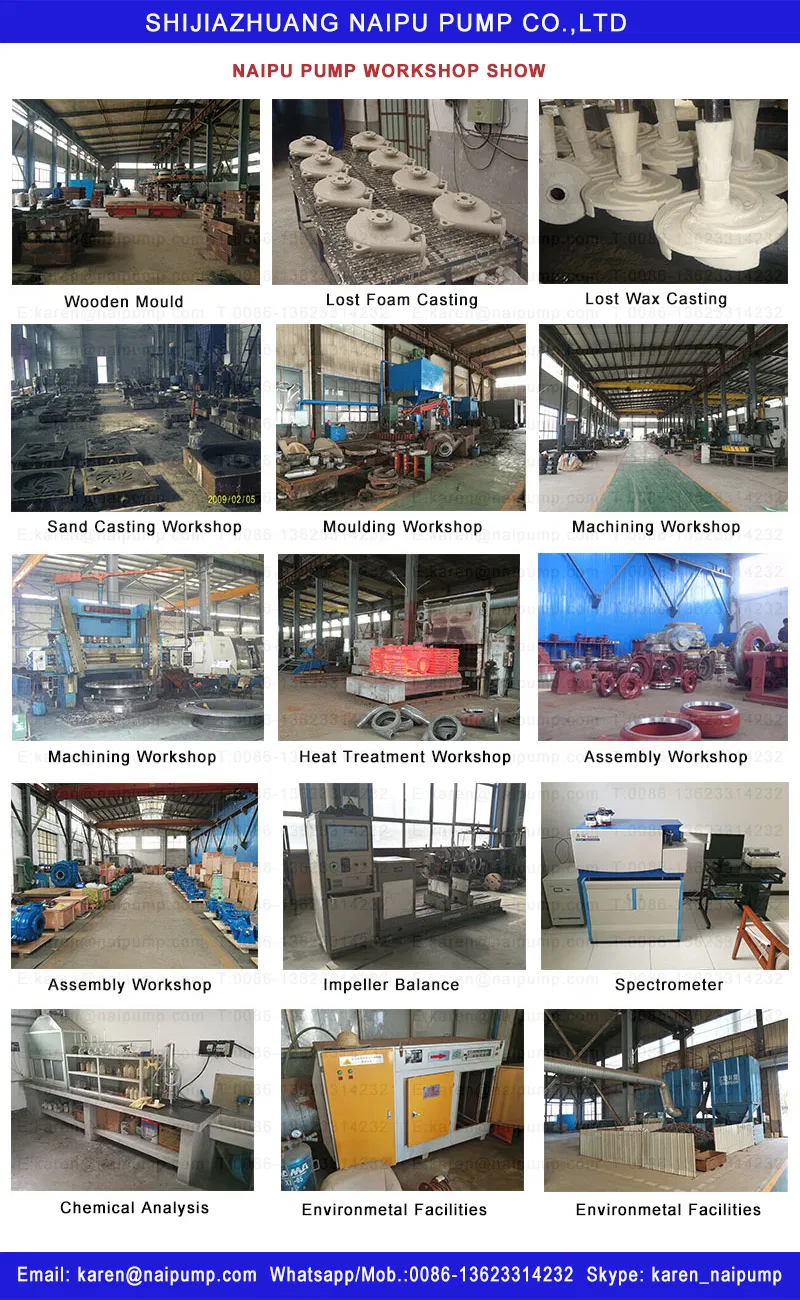

Naipu Workshop Show:

Naipu Advanced Inspection Facilities:

Applications

The parts are widely used in Main Applications: Heavy Mining | Mineral Processing | Sand and Gravel |Coal Prep | Cyclone Feeds | Aggregate Processing | Fine Primary Mill Grinding | Chemical Slurry Service | Tailings | Secondary Grinding | Industrial Processing | Pulp And Paper | Food Processing | Cracking Operations | Ash Handling | Pipeline Transport | High Velocity Hydraulic Transport |Food Processing | Explosive Sludge In Metal Smelting | River And Pond Dredging | Heavy Refuse Removal | Larger Particle Or Low NPSHA Applications | Continuous (Snore) Sump Pump Operation | Abrasive Slurries | High Density Slurries | Large Particle Slurries | Sump Drainage | Wash down | Floor Drainage | Mixing | Iron Ore | Cooper | Diamond | Alumina | Coal | Gold | Kaolin | Phosphorite | Steel | Palm | Suger | Chemical | Power | FGD | Frac Sand Blending | Construction | City Sewage | etc.

Possible Faults and Settlements

| Faults | Reason | Settlement |

| 1.Pump fails to discharge any water,The hand of pressure gauge beat violently | 1.Suction pipe don't have enough water. 2.Suction pipe blocked or the valve is locked. | 1. Inject enough water 2.unlock the inlet valve,clear the blocks 3.Exclude the air leakage |

| 2.The pump can't discharge water,the hand of vacuum meter beat heavily. | 1.The inlet valve is unlocked or silted up. 2.The resistance of suction pipe is too big or silted up. 3.The height of suction is too high. | 1.Unlock the valve or desilting 2.improve the design of suction pipe or desilt 3.Lower the height of the installation. |

| 3.The pump can't discharge water,pressure gauge shows heavy pressure. | 1.The resistance of the discharge pipe is too big. 2.The impeller blocked 3.The speed is slow. | 1.Check and adjust the outlet pipe. 2.Clear the impeller 3. Improve the speed. |

| 4.The pump doesn't rotate | The volute is silted up by the blocks. | Clear the blocks |

| 5.The capacity is not enough | 1.The blocks of the impeller or the inlet or outlet pipe. 2.The abrasion of the impeller is heavily. 3.The speed is low to normal 4.Pump is installed unreasonably or the leakage of the inlet pipe. 5.The transporting height is too high,the loss of the resistance of the inside pipe are too big. 6.The inlet valve not open enough or blocked 7.The packing seal leaks | 1.Clear the impeller or pipe. 2.Change the impeller 3.Adjust the speed 4.Install again or stop leaking.

|

| 6.The motor of the pump is overloaded | 1.The head of the pump exceeds the head of the working condition. 2.Not consider the slurry density when selecting the pump. 3.The packing press tightly | 1.Turn down the outlet valve,cut the impeller or lower the speed. 2.Select the motor again. 3.Adjust the the screw of the packing gland |

| 7.Abnormal sound in the pump, and no water out | 1.The resistance of the inlet pipe is too big. 2.The height of the suction is too high. 3.Cavitation occurred

|

|

| 8.pump vibrates | 1.pump cavitate 2.The block of the impeller single vane 3.The no concentricity between the pump shaft and motor shaft 4.Fasteners or foundation loose | 1.Adjust the water valve ,lower the height of the installation,reduce the resistance of the inlet. 2.Clear the impeller 3.Alignment again 4.Fasten the screw,and reinforce the foundation. |

| 9.Bearing is overheat | 1.lock the cooling water 2.lubrication is not good. 3.the lubrication oil is not clear 4.the wrong direction of the thrust bearing. 5.there is something wrong with the bearing. |

|

| 10.Packing short life | The material of packing is not good | Change the packing |

| 11.pump leak oil | 1.High oil level 2.The rubber parts invalid 3.Assembly problem | 1.Lower the oil level 2.Change rubber spares 3.Adjust the assembly |

| 12 Pump head leaking | 1.The rubber parts not press well | Assembly again or press tightly |

Contact Us

Contact Person: Karen Tan

Contact Person: Karen Tan

Related Category

Water Pump

Centrifugal Pump

Plunger Pump

Piston Pump

Diaphragm Pump

Gear Pump

Vacuum Pump

Pump Parts

Screw Pump

Gasoline & Gas Pump

Self-Priming Pump

Vane Pump

Other Pump & Vacuum Equipment

Pressure Pump

Jet Pump

Peristaltic Pump

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.