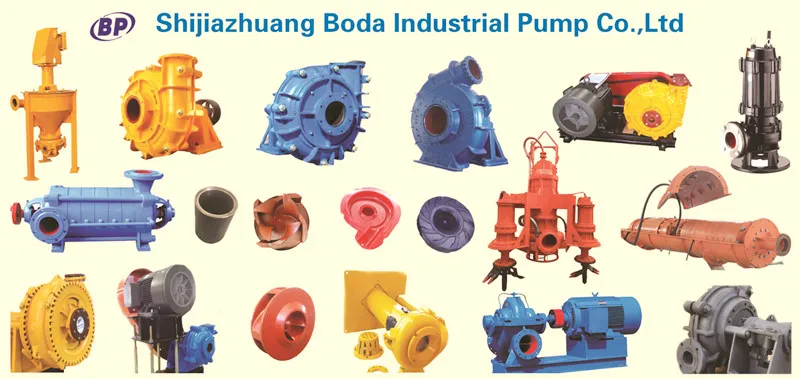

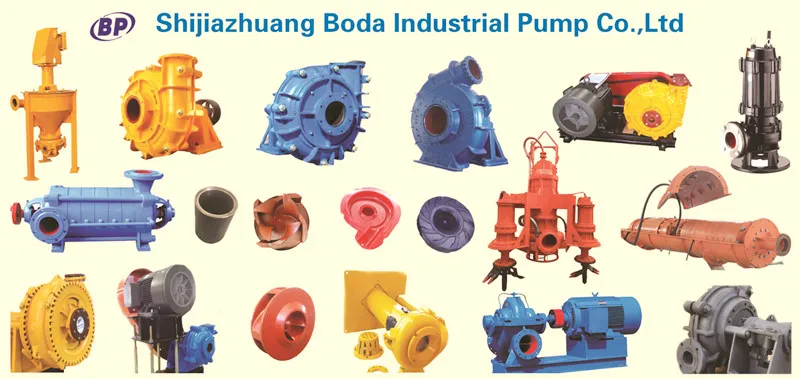

Heavy Duty High Pressure Mining Metal Lined Sludge Slurry Pump

Heavy Duty High Pressure Mining Metal Lined Sludge Slurry Pump:Model: BL, BM BH, BHHCapacity: 10.8~5400m3 /hHead: 3~118mMotor power: 15~1200KWIntroduction: BL BM, BH and BHH series pumps contain cantilever and horizontal centrifugal pumps, which apply to transport slurry with strong corrosion proof ......

Send Inquiry

Product Description

Heavy Duty High Pressure Mining Metal Lined Sludge Slurry Pump:

Model: BL, BM BH, BHH

Capacity: 10.8~5400m3 /h

Head: 3~118m

Motor power: 15~1200KW

Introduction: BL BM, BH and BHH series pumps contain cantilever and horizontal centrifugal pumps, which apply to transport slurry with strong corrosion proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on. The kind of pump can be used in series for multi stages. Its pump body consist of replaceable antifriction metal lining or rubber lining, and its impeller is made of antifriction metal or rubber. The pump body lining and impeller of BHH serial pump are made of antifriction metal only. The shaft seal of BL .BM, BH and BHH serials pumps may adopt packing seal or centrifugal seal. Pump outlet can be spaced by 45. According to requirement, and it may be installed by rotating eight different angles.

Introduction of Centrifugal Slurry Pump :

1. Abrasion and corrosion resisting

2. Material: hard alloy metal(Cr27,Cr28, Cr30, CD4MCu) or rubber liner optional,

3. Shaft seal: packing seal, expeller seal, and mechanical seal.

4. Power driver: electrical motor or diesel engine.

Application of Centrifugal Slurry Pump :

Deliver slurry with hard particle, in the mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries

1. Conveying mortar,slag which are strong corrosive and with solid particles.

2. Widely used in extracting sand, marine reclamation land,power plant,mining.

Features of Centrifugal Slurry Pump :

Component of Centrifugal Slurry Pump:

1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity.

2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance.

3. The parts such as labyrinth, labyrinth lock nut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life.

4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety.

Drive type of Centrifugal Slurry Pump:

DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor.

CV Type: The pump is driven by a belt connected to the crankshaft of the engine. This way of connection allows for saving space, easy installation, and fast adjustment of pumping speed. The motor is fixed to the motor support frame which is located on the bearing support above the slurry pump.

ZV Type: Another type of belt drive that allows easy adjustment of pumping speed. The motor is directly fixed to the bearing support. This way of installation is suitable for motors with larger horsepower than is possible with CV type of installation. Due to the installation of motor onto the bearing support, this method helps save installation space.

CR Type: This type of belt drive makes it easier to adjust pumping speed. The installation allows both the motor and slurry pump to be fixed to the ground. The motor is installed to the side of the pump. This installation method is suitable for large-power motors.

Structure Drawing:

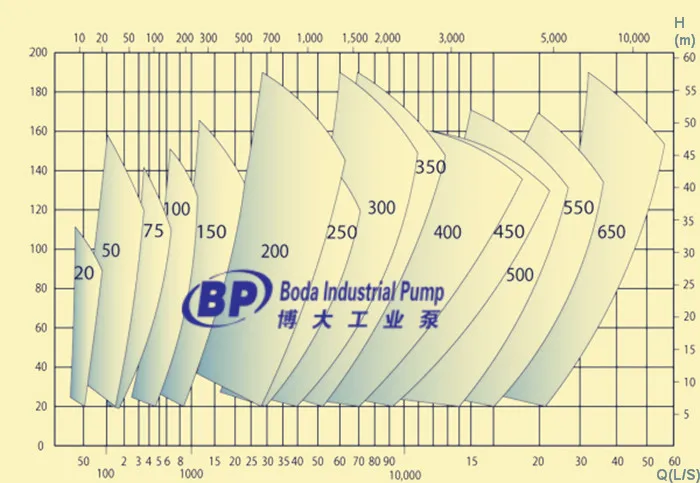

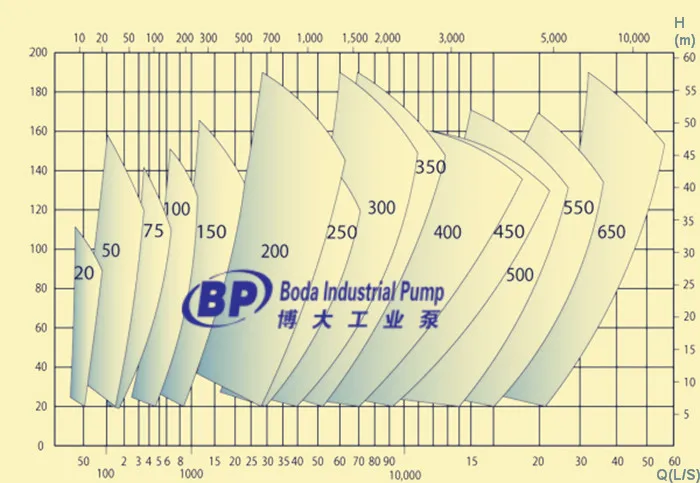

Selection Chart:

Model: BL, BM BH, BHH

Capacity: 10.8~5400m3 /h

Head: 3~118m

Motor power: 15~1200KW

Introduction: BL BM, BH and BHH series pumps contain cantilever and horizontal centrifugal pumps, which apply to transport slurry with strong corrosion proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on. The kind of pump can be used in series for multi stages. Its pump body consist of replaceable antifriction metal lining or rubber lining, and its impeller is made of antifriction metal or rubber. The pump body lining and impeller of BHH serial pump are made of antifriction metal only. The shaft seal of BL .BM, BH and BHH serials pumps may adopt packing seal or centrifugal seal. Pump outlet can be spaced by 45. According to requirement, and it may be installed by rotating eight different angles.

Introduction of Centrifugal Slurry Pump :

1. Abrasion and corrosion resisting

2. Material: hard alloy metal(Cr27,Cr28, Cr30, CD4MCu) or rubber liner optional,

3. Shaft seal: packing seal, expeller seal, and mechanical seal.

4. Power driver: electrical motor or diesel engine.

Application of Centrifugal Slurry Pump :

Deliver slurry with hard particle, in the mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries

1. Conveying mortar,slag which are strong corrosive and with solid particles.

2. Widely used in extracting sand, marine reclamation land,power plant,mining.

Features of Centrifugal Slurry Pump :

- Multi-purpose sand and gravel pump, high efficiency and energy saving.

2. Horizontal, centrifugal, one stage, single casing slurry pump.

3. Distinctive innovation in hydraulic and structural design.

4. Pump discharge direction can be changed in any 45 degree,easy installation.

5. Long-term bearing life: The bearing assembly is composed of large diameter shaft and short overhang.

Component of Centrifugal Slurry Pump:

1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity.

2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance.

3. The parts such as labyrinth, labyrinth lock nut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life.

4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety.

- All of the rubber parts have superior erosion resisting performance which can be used for a long life.

Drive type of Centrifugal Slurry Pump:

DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor.

CV Type: The pump is driven by a belt connected to the crankshaft of the engine. This way of connection allows for saving space, easy installation, and fast adjustment of pumping speed. The motor is fixed to the motor support frame which is located on the bearing support above the slurry pump.

ZV Type: Another type of belt drive that allows easy adjustment of pumping speed. The motor is directly fixed to the bearing support. This way of installation is suitable for motors with larger horsepower than is possible with CV type of installation. Due to the installation of motor onto the bearing support, this method helps save installation space.

CR Type: This type of belt drive makes it easier to adjust pumping speed. The installation allows both the motor and slurry pump to be fixed to the ground. The motor is installed to the side of the pump. This installation method is suitable for large-power motors.

Structure Drawing:

Selection Chart:

| Type BM BH | Allowable Mating Max.Power (kw) | Clear Water Performance | Impeller | ||||||

| Capacity Q | Head H (m) | Speed n (r/min) | Max EFF η(%) | NPSH) (m) | No of Vanes | Impel Dia(mm) | |||

| (m 3 /h) | (L/S) | ||||||||

| 1.5/1B-BH | 15 | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 5 | 152 |

| 2/1.5B-BH | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 5 | 184 |

| 3/2C-BH | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 5 | 214 |

| 4/3C-BH | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 5 | 245 |

| 4/3D-BH | 60 | ||||||||

| 6/4D-BH | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 5 | 365 |

| 6/4E-BH | 120 | ||||||||

| 6/4D-BH | 60 | 180-396 | 50-110 | 7-61 | 600-1600 | 55 | 3-8 | 4 | 372 |

| 6/4E-BH | 120 | ||||||||

| 8/6E-BH | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 5 | 510 |

| 8/6R-BH | 300 | ||||||||

| 8/6E-BH | 120 | 360-828 | 100-230 | 7-52 | 400-1000 | 70 | 2.5-6 | 4 | 536 |

| 8/6R-BH | 300 | 360-828 | 100-230 | 7-52 | 400-1000 | 70 | 2.5-6 | 4 | 536 |

| 10/8ST-BH | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 5 | 686 |

| 12/10ST-BH | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 5 | 762 |

| 14/12ST-BH | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 5 | 965 |

| 16/14ST-BH | 560 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 5 | 1067 |

| 16/14TU-BH | 1200 | ||||||||

| 10/8E-BM | 120 | 540-1440 | 150-400 | 14-60 | 600-1100 | 73 | 4-10 | 5 | 549 |

| 10/8R-BM | 300 | ||||||||

| Type BL | Allowable Mating Max. Power (Kw) | Clear Water Performance | Impeller | ||||||

| Capacity/ Q m ³ /hr | Head/m | Speed /rpm | Max Efficiency /% | NPSH /m | Nos of Vane s | Impeller Diameter /mm | |||

| 20A-BL | 7.5 | 2.34-10.8 | 6--37 | 1400--3000 | 30 | 4 | 152.4 | ||

| 50B-BL | 15 | 16.2--76 | 9--44 | 1400--2800 | 55 | 3.5--8 | 5 | 190 | |

| 75C-BL | 30 | 18-151 | 4--45 | 900--2400 | 57 | 3--6 | 4 | 229 | |

| 100D-BL | 60 | 50-252 | 7-46 | 800--1800 | 60 | 2--3.5 | 4 | 305 | |

| 150E-BL | 120 | 115--486 | 12-51.5 | 800--1500 | 65 | 2--6 | 4 | 381 | |

| 200E-BL | 120 | 234--910 | 9.5--40 | 600--1100 | 64 | 3-6 | 4 | 457 | |

| 250E-BL | 120 | 396--1425 | 8--30 | 500--800 | 77 | 2--10 | 5 | 550 | |

| 300S-BL | 560 | 468--2538 | 8--60 | 400--950 | 79 | 2-10 | 5 | 653 | |

| 350S-BL | 560 | 650--2800 | 10--59 | 400--840 | 81 | 3--10 | 5 | 736 | |

| 400ST-BL | 560 | 720--3312 | 7--51 | 300--700 | 80 | 2--10 | 5 | 825 | |

| 450 ST-BL | 560 | 1008--4356 | 9--48 | 300--600 | 80 | 2--9 | 5 | 933 | |

| 550 TU-BL | 1200 | 1980-7920 | 10-50 | 250-475 | 86 | 4-10 | 5 | 1213 | |

Related Category

Water Pump

Centrifugal Pump

Plunger Pump

Piston Pump

Diaphragm Pump

Gear Pump

Vacuum Pump

Pump Parts

Screw Pump

Gasoline & Gas Pump

Self-Priming Pump

Vane Pump

Other Pump & Vacuum Equipment

Pressure Pump

Jet Pump

Peristaltic Pump

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.